-

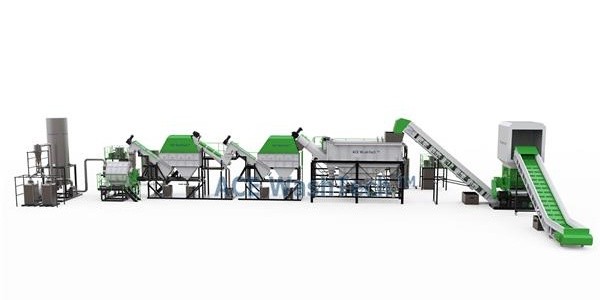

PE PP film washing line

Plastic recycling washing system is one of the main recycling series of ACE WashTech. This system has smart modular design aiming at agricultural film, industrial packaging film, bag, blow molding packaging bottle/ box, injection and electronic waste recycling. Including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular. Which can remove ferrous and nonferrous metals, sand, oil, glue, paper label and many other different contaminants efficiently. You can get a different module combinations design from ACE WashTech according to your requirements and material's condition. In range of different raw materials, ACE WashTech provides 300-10000kg/h economy and high-level production lines with different configurations.

Details -

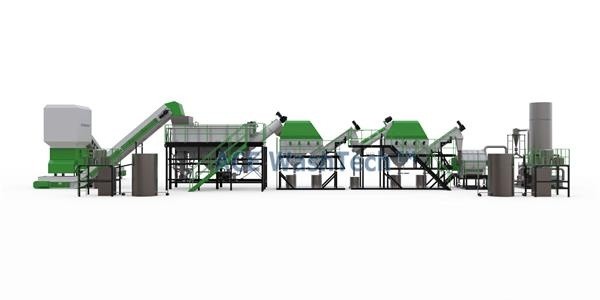

Rigid plastic washing line

Plastic recycling washing system is one of the main recycling series of ACE WashTech. This system has smart modular design aiming at agricultural film, industrial packaging film, bag, blow molding packaging bottle/ box, injection and electronic waste recycling. Including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular. Which can remove ferrous and nonferrous metals, sand, oil, glue, paper label and many other different contaminants efficiently. You can get a different module combinations design from ACE WashTech according to your requirements and material's condition. In range of different raw materials, ACE WashTech provides 300-10000kg/h economy and high-level production lines with different configurations.

Details -

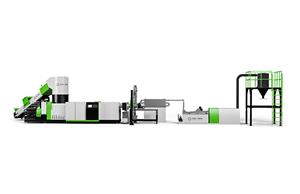

PET washing line

PET bottles/ flakes washing line is one of the main recycling series of ACE WashTech machinery. This system applies to waste PET plastics recycling with different pollution levels. Which can remove ferrous and nonferrous metals, sand , oil, glue, rubber, wood, PE/ PP/ BOPP labels and many other different contaminants efficiently. It also provides a good solution for mixed color PET and materials containing PVC. The modular design makes it easy to have different combinations according to the requirements of the customers, such as bottle to fiber, bottle to flake, bottle to bottle washing system. ACE WashTech provides 500-6000kg/h economy and high-level automatical production lines with different configurations.

Details -

Single shaft shredder

ACE WashTech provides four different types of Shredder and Crusher for different plastic material processing, AGH, AGS, AGF, AGX. AGS General Purpose Single Shaft Shredder has Hydraulic screen cradle, gearbox with shrink disc, rotor cooling, pipe spacer, touch screen PLC, hopper mounted viewing mirror, increased motor drive, hydraulic drive.

Details -

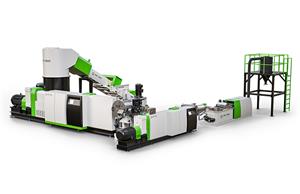

Heavy duty granulator

ACE WashTech provides four different types of Shredder and Crusher for different plastic material processing, AGH, AGS, AGF, AGX. AGH General Purpose Heavy Duty Granulator has extra flywheel, double infeed hopper, roller feeder, mounted screw feeders in hopper, winding protection, metal detector, metal separatoe, besoke colour scheme, increased motor drive.

Details -

Single shaft heavy duty shredder

ACE WashTech provides four different types of Shredder and Crusher for different plastic material processing, AGH, AGS, AGF, AGX. AGX Heavy Duty Single Shaft Shredder has Hydraulic screen cradle, gearbox with shrink disc, rotor cooling, pipe spacer, touch screen PLC, hopper mounted viewing mirror, increased motor scheme, turbo hydraulics, housing wear plates.

Details