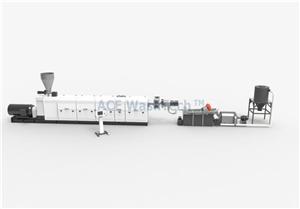

China pet plastic pelletizing machines plastic line Factory Brands

pet plastic pelletizing machines plastic line

China pelletizing machine plastic

"I've seen everything in this industry, " says Mr Kraft. ""The ups and downs of the market, the development of technology. It was certainly an incredible journey. "

Niagara's recycling pioneered recycling in the area in the 1970s. In 1985, they implemented a second home recycling blue box program in Ontario - probably the second in Canada after nearby Chichina-Waterloo.

"By the early 1990s, all 12 cities in the region had blue box programs," Craft said. "In 1996, the Niagara region assumed responsibility for all waste management, including recycling, and since then we have been in a mutually beneficial partnership with them for 23 years. "

Initially, as a non-profit social enterprise company, Kraft explained that Niagara Recycling was founded in collaboration with another non-profit organization called NTEC (Niagara Training and Employment Center), whose sole mission is to help people with disabilities.

"We started out as a member of NTEC, where we would integrate adults with developmental disabilities into our workplace," he explains. "There was very little equipment, probably only a few conveyor belts, most of them hand-sorted newspapers... This is a far cry from the complexity currently used in MRFs. "

He added that, to his knowledge, the Niagara Recycling Company's partnership with the Niagara region, as well as the region's social mission, was not the same size model mrFs had adopted elsewhere.

"Most MRF Ontario is made up of large companies in many cities in North America, which is quite unique in this close relationship with our region," he said, adding that their facilities also include an MRF education component through which they conduct public tours and school visits. "As this is a public asset, it is important to show facilities to the community.

The processor is not the only one that uses purified compounds. Sometimes machine manufacturers need them. Especially those companies with laboratory production lines that are used by customers for testing, research and development, and scaling up.

pet pelletizing machines Brands

Coperion Corp. is one such example, a leading supplier of twin screw composite extruders. At its laboratory in Sewell, New Jersey, the machine manufacturer has three production lines from its ZSK series of co-turned twin screw extruders, equipped with various types of ball system. "Labs are often busy with customers experimenting or testing recipes," says Justyn Pyz, a process engineer at Coperion. Sometimes the customer runs multiple tests in a few days. They may one day do experimental design (DOE) on one formula, and then come back the next day to do another. At the Coperion test lab, this means a thorough clean-up between runs, sometimes even including screw pulls. When the customer completes their tests, the complete removal is completed.

For several years, Coperion has been purifying it with low melting point flow polyethylene left over from customer tests. This material is powdered, so the resin must be granulated before it can be used as a purification mixture. As the supply of the material began to decline, Coperion began looking for alternatives and encountered iD additives at a conference in 2017. They are individually packaged and the operator can clean the machine by placing the package in the feed/throat/hopper of the machine. They are said to apply to all resin types on all plastic machinery, including injection, extrusion and blow molding. The typical dose is one ounce per inch. Screw diameter. No immersion or temperature adjustment is necessary.

plastic pelletizing line Factory

The origins of CPM can be traced back to 1883 in Napa Valley, California, when Toulouse de Lorieux Co. There, presses, crushers and stems are produced for the wine industry. Nearly 50 years later, at the height of the Great Depression in 1931, the company built its first billiard grinder, a 30-horsepower flat bed with a fixed flat mold. With this development, CPM was born. Over the next few decades, CPM created more ball mill models with additional features.

The company's acquisition phase began in the 1980s, when it acquired Roskamp Roller Mill Co. and Champion Hammermills, creating Roskamp Champion. At the end of 2017, Roskamp Champion produced the 500th SP3200 flatpress, which became the standard for the oilseed processing industry. The next acquisition came in 2002, when CPM acquired Beta Raven, a leading supplier of automation and dosing systems for feed plants. Since then, the company has absorbed many different equipment and processing companies, including Crown Iron, SKET, Century Exsqueezing, Wolverine Proctor, Nanjing Rea Polymer Processing Equipment, Greenbank Technology, and especially the Italian company Di Piu Macchine in the biomass energy industry. Impianti.