plastic extruder

-

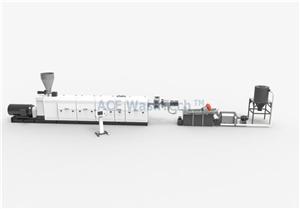

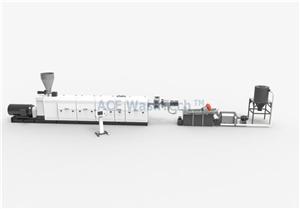

AWTS 80 Single Screw Extrusion System

1. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc. 2. Configure intelligence and controllable system, can realize the whole system start/stop automatically. 3. Longer processing length, optimized screw structure, to guarantee the final pellet's quality. 4. Lower energy consumption with high output. 5. Lower investment cost for a high quality and durable machine. 6. Fast machine delivery and installation.

single screw pelletizer plastic recycling system with single screw pp granulation system with one screw single screw system for pelletizingEmail Details -

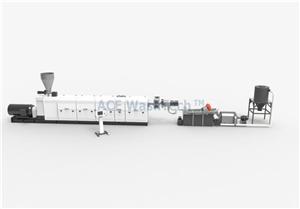

AWTS 180 Extrusion And Pelletizing System

1. Lower investment cost for a high quality and durable machine. 2. Configure intelligence and controllable system, can realize the whole system start/stop automatically. 3. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc. 4. Longer processing length, optimized screw structure, to guarantee the final pellet's quality. 5. Lower energy consumption with high output. 6. Fast machine delivery and installation.

Email Details -

Hot

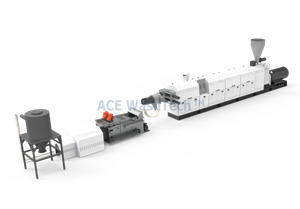

AWTS 100 120 Two-stage Extrusion And Pelletizing System

1. Lower investment cost for a high quality and durable machine. 2. Fast machine delivery and installation. 3. Configure intelligence and controllable system, can realize the whole system start/stop automatically. 4. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc. 5.Three kinds of pelletizing systems are optional to handle different type of rigid plastic scraps. 6. Longer processing length, optimized screw structure, to guarantee the final pellet's quality. 7. Lower energy consumption with high output.

HDPE recycling machine pp-r plastic extruder single screw extruder with two extrusion stages plastic extruder with one screwEmail Details -

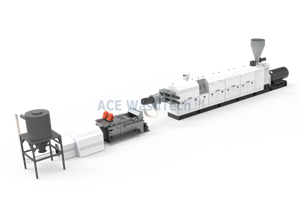

AWTS 180 200 Two-stage Extrusion And Pelletizing Line

1. Configure intelligence and controllable system, can realize the whole system start/stop automatically. 2. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc. 3.Three kinds of pelletizing systems are optional to handle different type of rigid plastic scraps. 4. Longer processing length, optimized screw structure, to guarantee the final pellet's quality. 5. Lower energy consumption with high output. 6. Lower investment cost for a high quality and durable machine. 7. Fast machine delivery and installation.

Email Details -

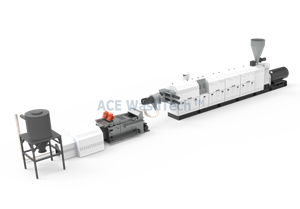

PP PE Bottle Extrusion And Pelletizing System

1. Lower investment cost for a high quality and durable machine. 2. Fast machine delivery and installation. 3. Configure intelligence and controllable system, can realize the whole system start/stop automatically. 4. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of flakes, agglomerates,squeezed film, etc. 5.Three kinds of pelletizing systems are optional to handle different type of rigid plastic scraps. 6. Longer processing length, optimized screw structure, to guarantee the final pellet's quality. 7. Lower energy consumption with high output.

special design screw plastic extruder with single screw three zone screw with shera section three zone screw for soft PVC extrusionEmail Details