Sales China Rigid Plastic flakes pp pe film washing line Price

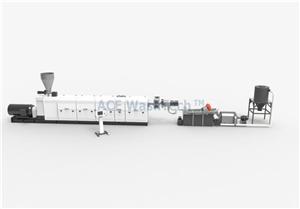

Rigid Plastic flakes pp pe film washing line

China Plastic flakes washing line

Hubbard Hot Cleaning System is a custom configuration that best suits the grooves of various components of the application, possibly including multi-compartment separator tanks, friction washers, turbine washers, mechanical or hot air dryers.

Usually, the system is used online as part of a continuous process. However, when cleaning is the most important time, the hot cleaning process can be carried out offline, allowing users to adjust the residence time of the mixing tank to achieve the required cleaning level, the company said in a press release.

Indorama Ventures is one of the world's largest producers of pressed plastics. In response to customer demands for more recyclable plastics, the company and other global plastics manufacturers have invested in the recycling industry. Earlier this year, Indorama acquired a custom polymer PET recycling plant in Athens, Alabama. The company also works with technology start-ups, including Loop Industries in Canada, which is commercializing a pet depilation technology.

Located in Guadalajara, the plant is part of the EcoMex joint venture. Guadalajara is the second largest city in Mexico after Mexico City. In 2014, Indorama acquired 51% of the then M. M. company. The polymer bought the plant. At that time, M.M. polymer was already a supplier of Indorama chips.

Sales pp pe film washing line

EcoMex supplies flake resins to Indorama Resin Manufacturing Plant 250 miles away from Cretaro. The factory uses raw materials to produce resins for future pet brands.

Yash Awasthi, vice president of Indorama Ventures North America, said in a press release from Amut: "Cleaned pet flakes will be used to produce new resins for sustainable products, and our customers now need their pet packaging products." "Our goal is to close recycling and improve the sustainability of pet containers."

The cleaning equipment will include a label removal machine to remove labels, especially the whole body contraction casing labels. Prewashing and peeling occur in cold water. Then the bottle enters the turbine and rubs against the washing machine using hot water. Mut, headquartered in northern Italy, said friction had intensified as the bottles were expected to be dirty.

Rigid plastic washing line Price

Manufacturers of food and other packaging-intensive products need large quantities of uniformly reusable plastic particles/sheets. Herbert Meckheim of Smithfield, Rhode Island, USA, said in a press release that when the hot cleaning system is integrated into a new or existing plastic recycling line, it comes from Smithfield, Rhode Island. Smithfield's Herbold Meckesheim American system can help processing plants meet this demand.

Herbert Meckheim Company is a subsidiary of German Herbert Meckheim Company. It designs, manufactures and installs diameter-changing equipment and production line systems for the plastic industry. The company's Herbold Hot Cleaning System was originally designed for polyphenylene glycol (PET) bottles and can be used in a variety of other projects, including thermoforming foil, pallets and foil for the packaging industry.

According to a press release by Herbert Meckheim, fat impurities in emulsion, cooking oil or sunscreen residues dissolve and are washed away, and residues of labels and adhesives are washed away. At the front end of the process, the removal of impurities results in larger, essentially clean, usable scales. This method of improving the cleanliness of sheets has been demonstrated by significantly reducing the number of particles found in extruded melt filters - usually 50% less than non-hot-washed sheets. The resulting clean scales also reduce odor, complete transparency and yellowness.