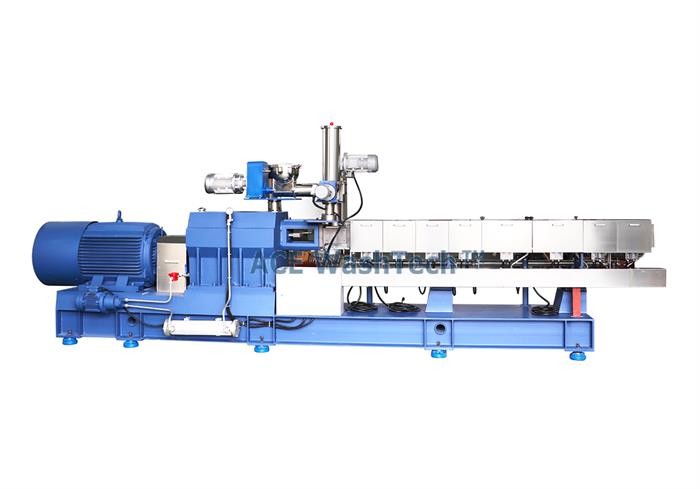

KSK 35 Filler Or Modification Granulation Line

- ACE WashTech

- China

- 45 days

- 100 sets

1.Closed circulation cooling and building block type barrel adopts independent heating and temperature control;

2.High torsional gear box is with a high safety factor, low noise, long service life;

3.Using High-performance oil lubrication system with a much longer life;

KSK 35 Filler Or Modification Granulation Line

Introduction

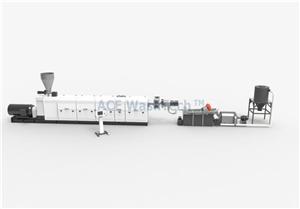

KSK Series PET pelletizing line is reliable recycling technology for the in-house recycling of PET flakes from bottles, preforms, strapping bands and sheets as well as for the recycling of post-consumer bottle flakes after the washing process. The end product is melt-filtrated, uniform granulate that can be used for a wide range of applications (bottles containers, sheets, fibers and nonwovens, strapping) With a capacity range is 150-1000 kg/h.

Dryer hopper for heating and moisture

Heating each 5-7 hours to remove moisture

Screw loader

Controlled by ABB/Schneider inverter

Parallel Twin Srcew Extruder

Hydraulic screen changer

Three types optional pelletizing system

Strand Pelletizing line for filling, copmpounding and fiber reinforcement.

Water-ring Die-face pelletizing line for filling and compounding

Under-water pelletizing line

Electric control cabinet

TECHNICAL SPECIFICATION

| Model | L/D | Rotary Speed | Capacity | Motor power |

| KSK 35 | 36-40 | 600-700 rpm | 30-70 kg/h | 15-22 KW |

| KSK 50 | 36-44 | 500-700 rpm | 80-200 kg/h | 30-45 KW |

| KSK 65 | 36-48 | 500-700 rpm | 200-400 kg/h | 45-75 KW |

| KSK 75 | 36-52 | 500-700 rpm | 350-700 kg/h | 110-160 KW |

| KSK 95 | 36-52 | 500-600 rpm | 700-1100 kg/h | 250-355 KW |