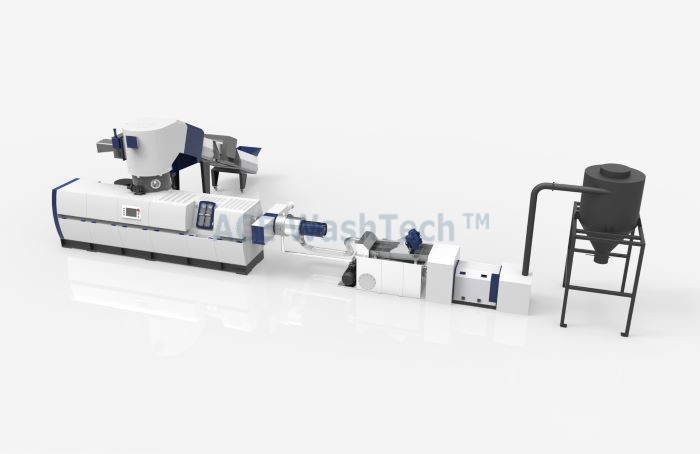

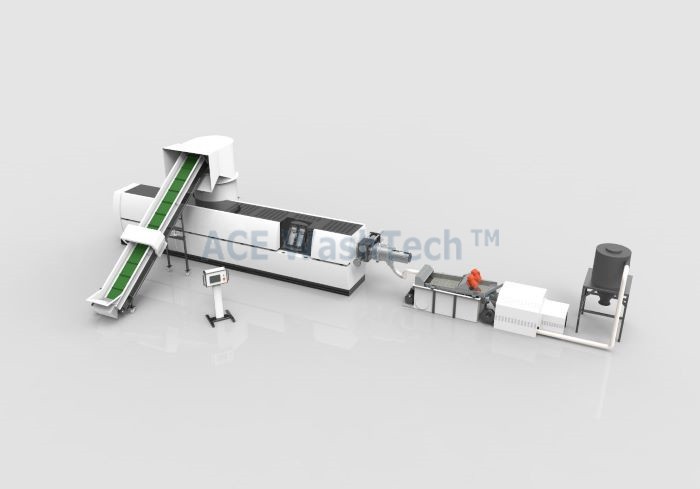

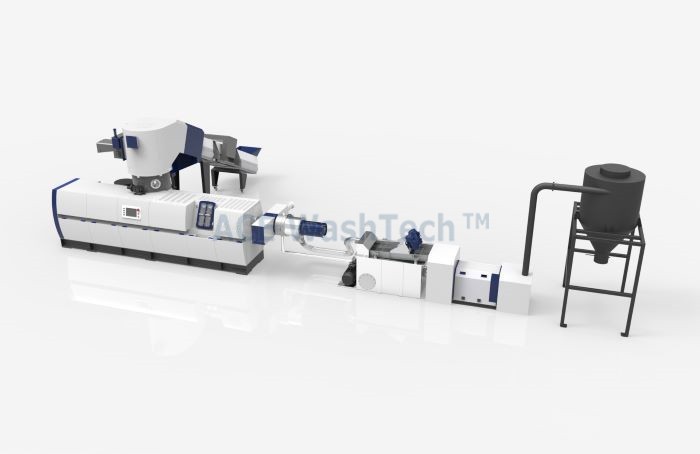

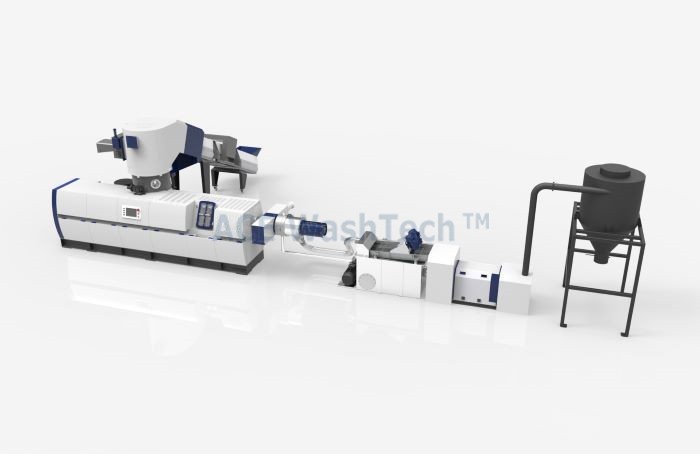

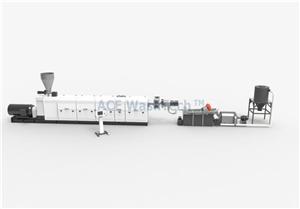

Plastics Compactor And Granulator

- ACE WashTech

- China

- 45 days

- 100 sets

1. Modular design, configuration can be adjusted according to the actual materials condition, especially suitable to materials in form of film, bag, tape, etc.

2. Longer processing length, optimized screw structure, to guarantee the final pellet's quality.

3. Higher output and lower energy consumption.

4. Lower investment cost for a high quality and durable machine.

5. Fast machine delivery and installation.

6. Configure intelligence and controllable system, can realize the whole system start/stop automatically.

INTRODUCTION

Washed plastic film as well as post-industrial plastic waste in the form of rolls, cut-offs, bags, scraps, foam could be recycled in the AWTech series compacting and pelletizing system. Will get high quality and uniform size final granules which could be reused back into the plastic products making line.

The AWTech series compacting and pelletizing system combines function of compacting, extrusion and pelletizing into one step. It provides best solution for PP/PE film, raffia, filament, bag, woven bag, nonwoven fabric and EPS foam materials recycling.

Compacting and extrusion unit

Compactor

Compactor makes material crushed, dried and compacted in one step, which enables a fast and stable feeding from the compactor directly into the extruder.

The rotatory blades will cut the material. Frictional heating caused by high speed rotatory blades will heat and make material shriking. Guide structure with special design compacts the material and directs it into extruder screw.

Specialized single screw extruder

34D or 36D processing section of extruder ensures perfect plasticization.

With double-zone vacuum degassing system, volatiles and moisture will be removed efficiency.

Precise temperature control system.

TECHNICAL SPECIFICATION

Model | Compactor volume | Compactor Motor power | Diameter of screw | L/D | Screw extruder motor power | Output capacity |

AWTech 80 | 300 L | 37 KW | 80 mm | 36 | 45/55 KW | 160-220 kg/h |

AWTech 100 | 500 L | 55 KW | 100 mm | 36 | 90/110 KW | 300-380 kg/h |

AWTech 120 | 800 L | 90 KW | 120 mm | 36 | 132 KW | 450-480 kg/h |

AWTech 140 | 1000 L | 110 KW | 140 mm | 36 | 160/185 KW | 500-650 kg/h |

AWTech 160 | 1200 L | 132 KW | 160 mm | 34 | 220/250 KW | 800-1000 kg/h |

AWTech 180 | 1400 L | 160 KW | 180 mm | 34 | 315 KW | 1000-1200 kg/h |