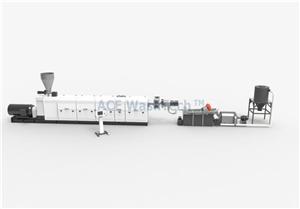

Soft Plastic Washing Recycling Line

- ACE WashTech

- China

- 45 days

- 100 sets

Higher output and lower energy consumption.

Low water consumption, 95%recycled-release.

Lower investment cost for a high quality and durable machine.

Auto control system.

Control mofule system.

Fast machine delivery and installation.

INTRODUCTION

Ability

Thanks to innovative washing technology and high quality performance. Removes the most difficult contaminants from PP/ PE/ PS/ ABS plastic materials. Cleans post consumer film, agricultural film, Rigid bottle/ drum, Battery case, WEEE plastic and even heavily contaminated woven bag fibre material. Provides almost 100% purity washing results.

Stability

PP PE film washing line is available for 24 hours working non-stop operation. Optimized design and top brand components to each module. Which could minimize the downtime ratio and save the maintenance time. This ensures the maximum availability and highest productivity for user.

Efficiency

PP PE film washing line is designed in all details for efficiency improving. The modular design could simplifies the planning and accelerates the implementation. The system have very low consumption values for electricity, water and chemicals. The operating costs and maintenance costs are absolutely reduced. Consistently the lowest investment costs and highest value creation!

Modularity

PP PE film washing line is a flexible modular system. All elements required by any customer for different application could be combined freely. This design reduces planning, construction and assembly time effectively. And it’s possible to adjust the system with regard to technological modification and market changing. This makes the investment future-proofing!

Intelligent control

Intelligent automatic modular control of PP PE film washing line. One main control panel with modern Touch Display for efficient interaction of all component. Multi-language available for operating system.

Turnkey service

PP PE film washing line is a flexible and customer-oriented recycling solution. The proposal is integrated and engineering project. Building design, overseas installation, commissioning and training are available. Machine warranty with spares in stocking and in-time delivery. Consistently quick and careful service in pre-sales and after-sales process.

BASIC DATA OF WASHING

| Model | ECO 300 | PRO 300 | ECO 500 | PRO 500 | ECO 750 | PRO 750 | ECO 2000 | PRO 2000 |

| Capacity for film | 220-350 kg/h | 220-350 kg/h | 450-550 kg/h | 450-550 kg/h | 750-1000 kg/h | 750-1000 kg/h | 1800-2200 kg/h | 1800-2200 kg/h |

| Installed power | 163 KW | 167 KW | 215 KW | 223 KW | 168 KW | 362 KW | 744 KW | 910 KW |

| Working power | 114 KW | 121 KW | 161 KW | 167 KW | 126 KW | 271 KW | 560 KW | 700 KW |

| Fresh water consumption | 0.5-1 m3/h | 0.5-1.5 m3/h | 0.5-2 m3/h | 1-2.5m3/h | 3-5 m3/h | 3-5m3/h | 8-10 m3/h | 8-10 m3/h |

| Moisture of output | <7% | <7% | <7% | <7% | <7% | <7% | <7% | <7% |

| Operation staff | 3 | 3 | 3 | 3 | 4-5 | 5-6 | 5-6 | 5-6 |

| Dimension (L*W*H)M | 18*4*8 | 20*4*8 | 22*4*8 | 36*4*8 | 47*4*8 | 58*5.5*8 | 74*6.5*8 | 83*6.5*8 |